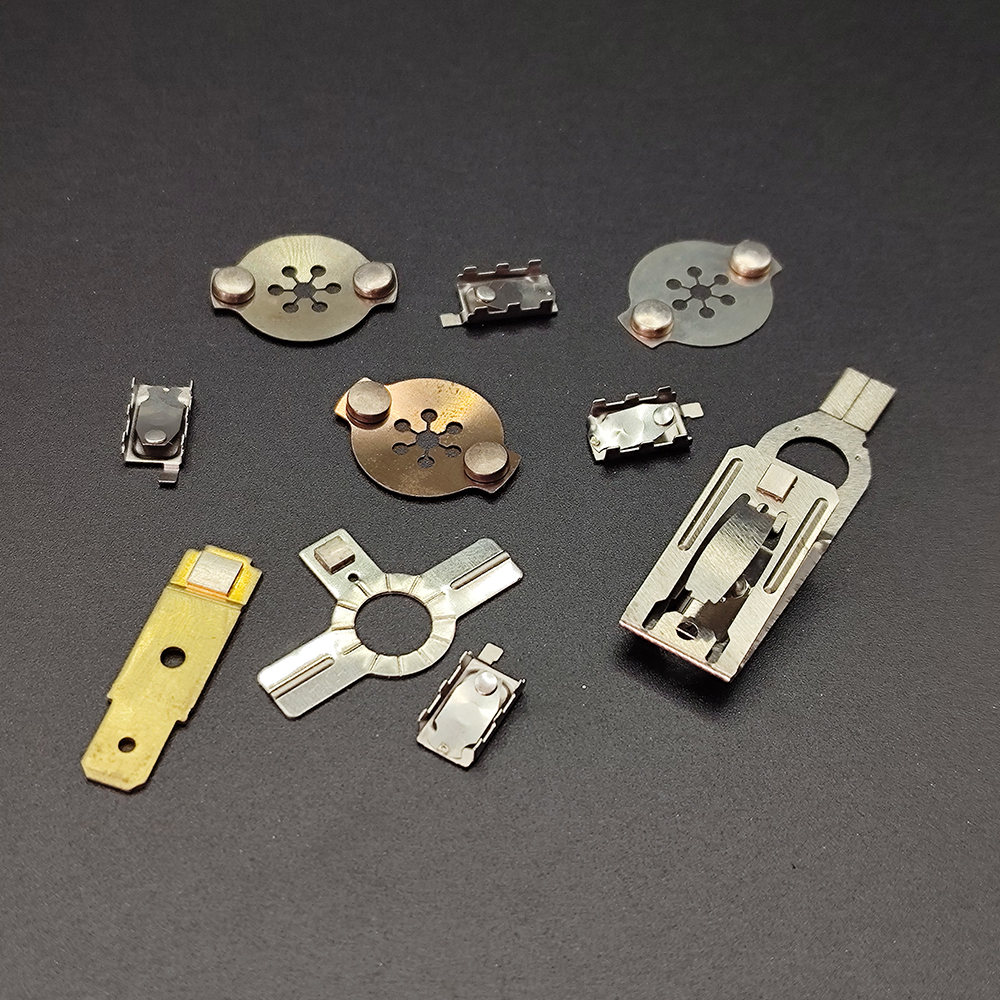

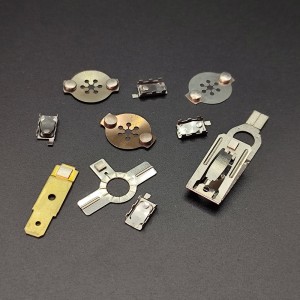

Resistance Welding Assemblies

Application

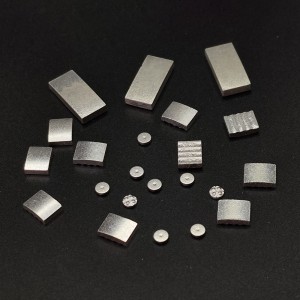

Silver contacts resistance welding is a special resistance welding technology, its advantages are as follows: Efficient and fast: silver point resistance welding can complete the welding process in a short time, with high efficiency, suitable for large-scale production. Good electrical conductivity: Silver point resistance welding can effectively weld silver points to the pads of electronic devices, and has good electrical conductivity, which is conducive to the conduction of current.

High-strength welding points: Silver point resistance welding can produce stable and firm welding points through high-temperature heating and pressure, with high strength and reliability. Low heat-affected zone: Due to the short welding time of silver point resistance welding, the heat-affected zone is small. For some materials that are sensitive to heat influence, such as electronic components, the impact on other parts can be reduced.

Easy to automate: The silver point resistance welding process can be combined with automation equipment to realize the automatic operation of the production line and improve the efficiency and consistency of welding.

Environmental protection: The silver point resistance welding process does not require additional welding materials, does not produce harmful gases or waste, and is environmentally friendly.

The design requirements of resistance welding Assemblies include material selection, surface cleaning, parameter control, solder joint layout, electrode material selection and detection and evaluation. Through reasonable operation and control, the quality and reliability of resistance welding can be ensured.