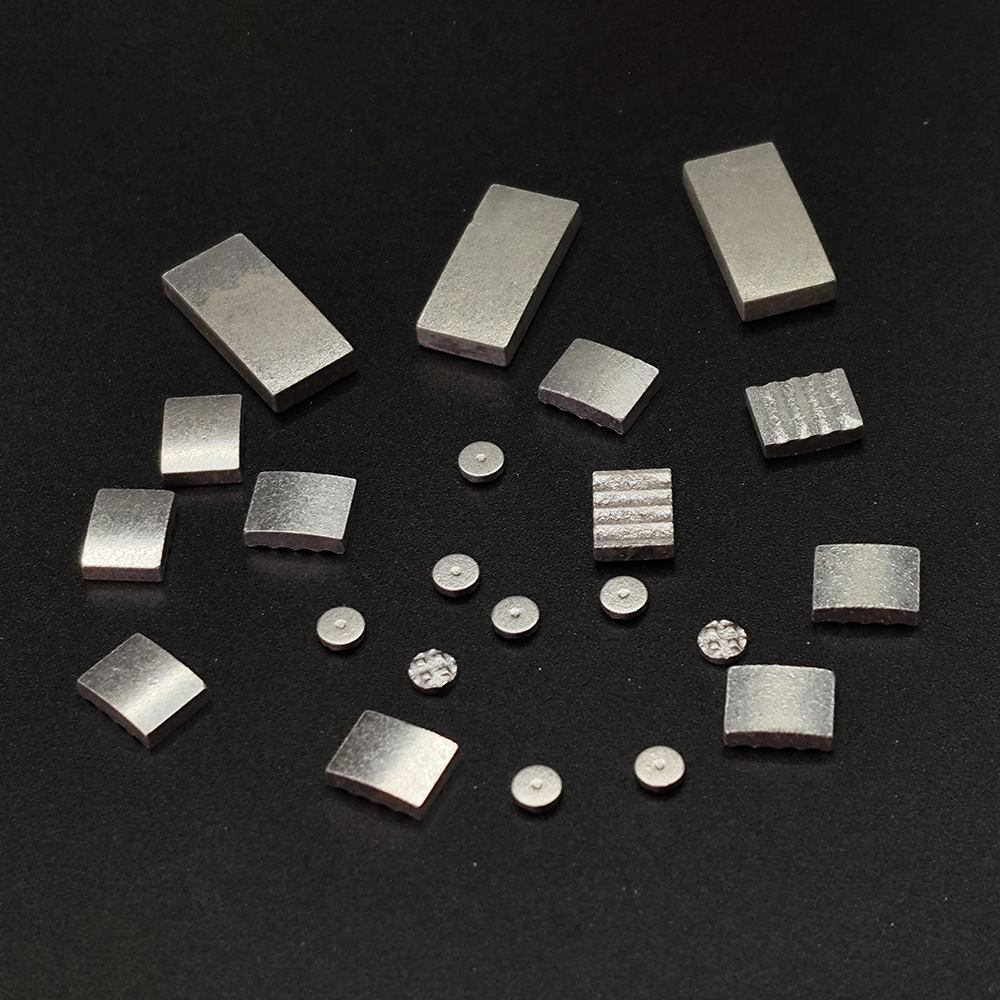

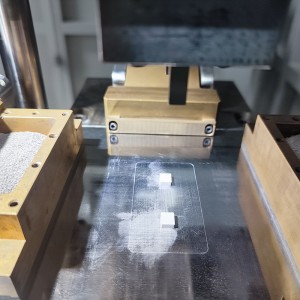

Tailored Powder Metal Contacts

Silver Tungsten (AgW)

Silver tungsten contacts are a common electrical component made of a combination of silver (Ag) and tungsten (W). Silver has good electrical conductivity and electrical conductivity, while tungsten has a high melting point, high hardness and wear resistance. By alloying silver and tungsten, silver tungsten contacts provide stable electrical contact and durability. Silver tungsten contacts are commonly used in high current, high temperature and high load applications such as electronic equipment, circuit breakers and resistors. They have good electrical conductivity, low contact resistance and excellent wear resistance, and can maintain good electrical contact and work stably, while being able to withstand certain arcs and high-temperature heat. In short, silver tungsten contacts are alloy materials composed of silver and tungsten, which have good electrical conductivity, electrical conductivity, wear resistance and high temperature resistance. They are widely used in the electrical industry to provide reliable electrical contact and stable working performance.

|

Product name |

Ag Component(wt%) |

Density |

Conductivity |

Hardeness(HB) |

|

(g/cm3) |

(IACS) |

|||

|

AgW50 |

50±2.0 |

13.2 |

57 |

130 |

|

AgW65 |

35±2.0 |

14.6 |

50 |

160 |

|

AgW75 |

25±2.0 |

15.4 |

41 |

200 |

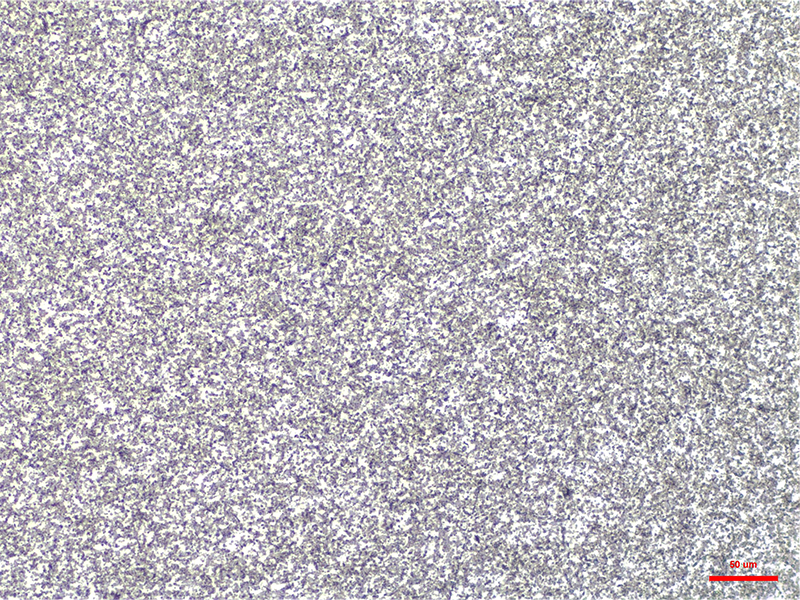

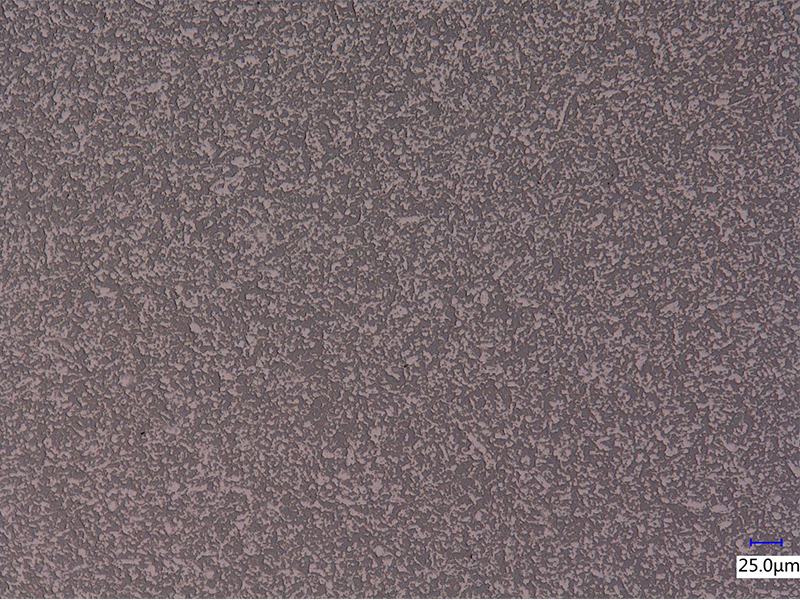

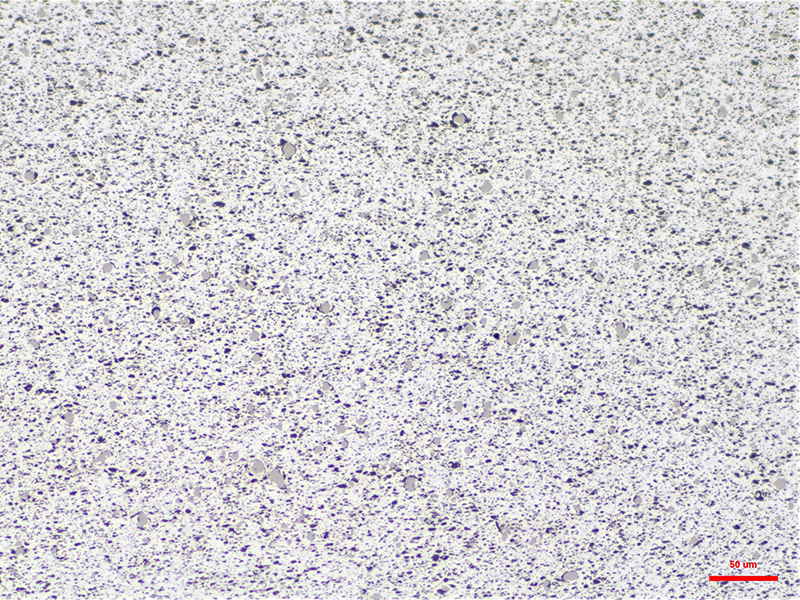

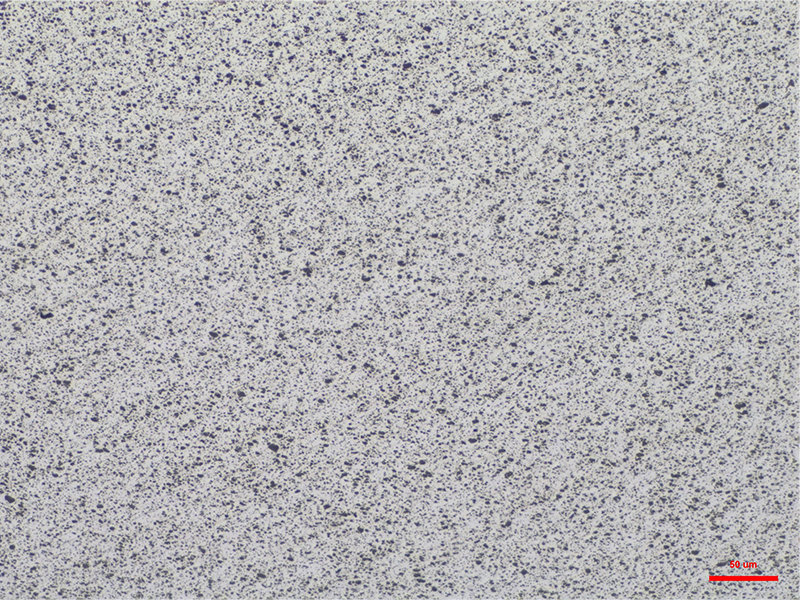

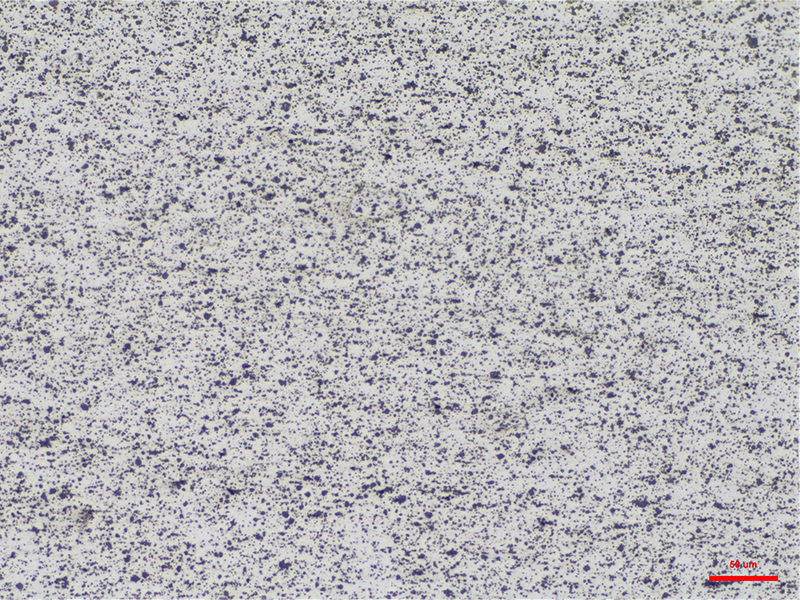

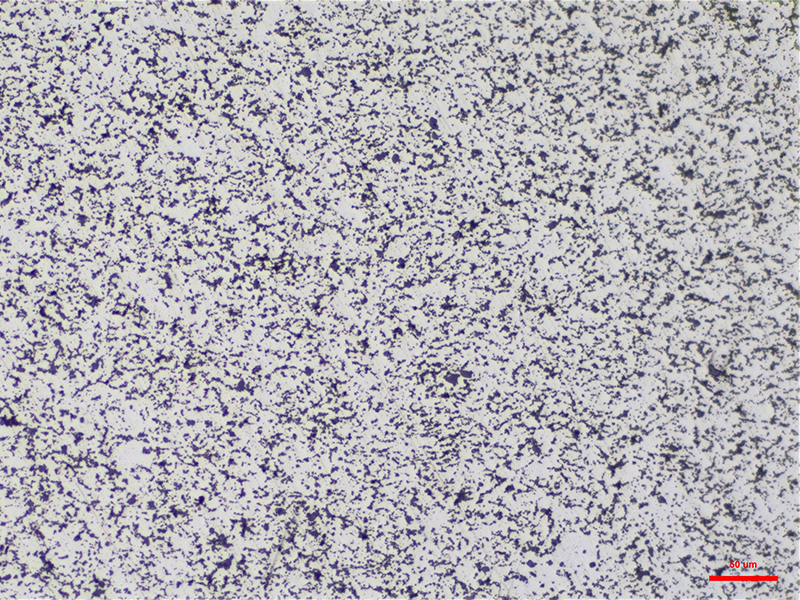

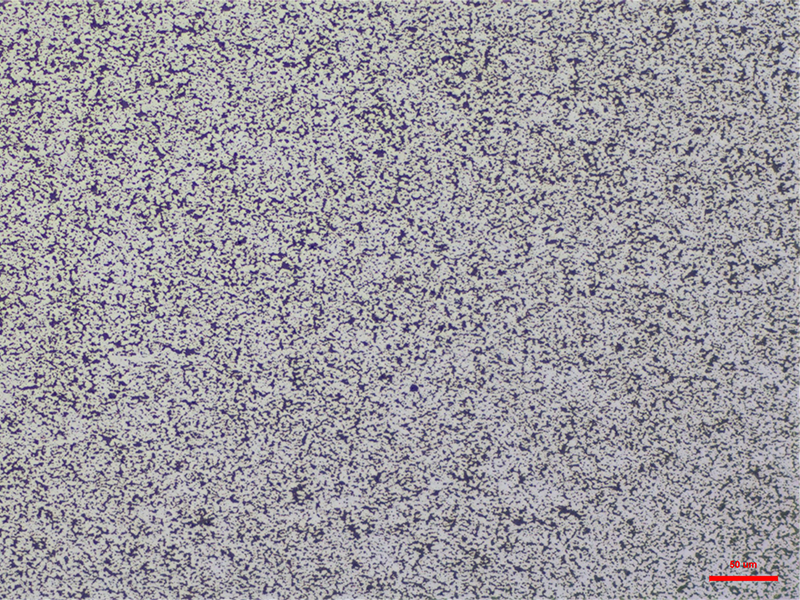

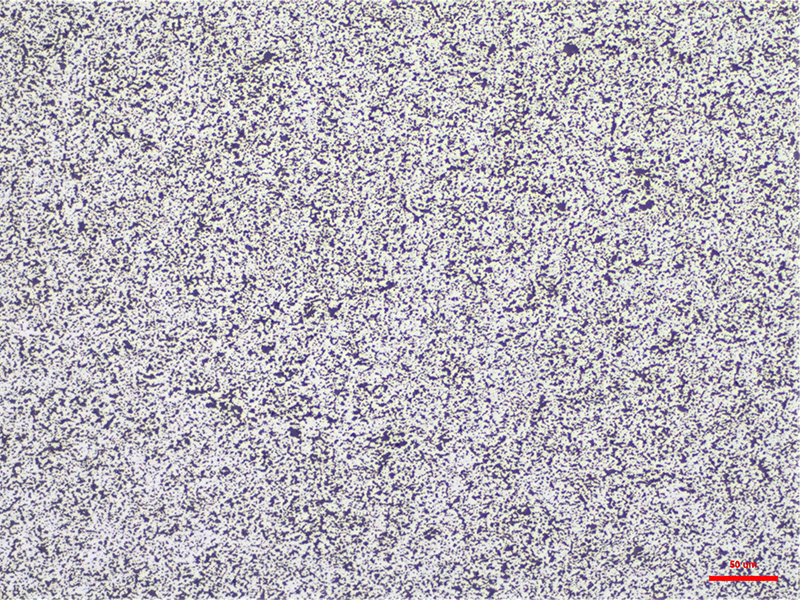

Metallographic Display

AgW(50) 200X

AgW(65) 200X

AgW(75) 200X

Silver Tungsten Carbide (AgWC)

Silver tungsten carbide contacts are a special contact material that is a combination of silver (Ag) and tungsten carbide (WC). Silver has good electrical conductivity and electrical conductivity, while tungsten carbide has high hardness, high melting point and wear resistance. Silver tungsten carbide contacts have high hardness and wear resistance, and can maintain stable electrical contact for a long time under high load and high temperature conditions. The hardness of tungsten carbide gives the contacts good mechanical stability against high voltages, high currents and frequent switching operations. The conductivity of silver tungsten carbide contacts is better than that of pure silver contacts, especially at high temperature and high load. Silver tungsten carbide contacts provide lower contact resistance and more stable electrical performance. Therefore, silver tungsten carbide contact material is a high-performance choice and is widely used in electrical equipment that requires high wear resistance, high temperature and high load, such as switches, relays and circuit breakers, etc. They provide reliable electrical contact and long life for a variety of harsh operating environments.

|

Product name |

Ag Component(wt%) |

Density |

Conductivity |

Hardeness(HV) |

|

(g/cm3) |

(IACS) |

|||

|

AgWC30 |

70±3 |

11.35 |

59 |

125 |

|

AgWC40 |

60±3 |

11.8 |

50 |

140 |

|

AgWC50 |

50±3 |

12.2 |

40 |

255 |

|

AgWC60 |

40±3 |

12.8 |

35 |

260 |

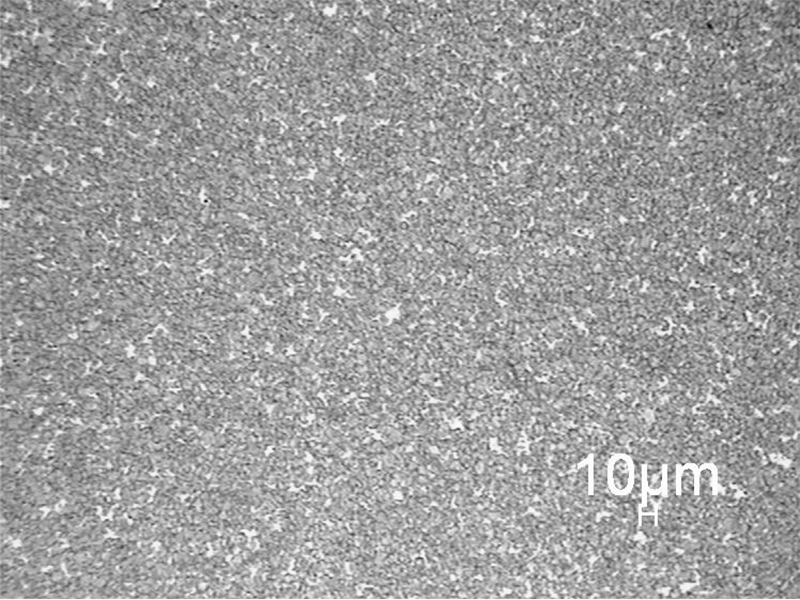

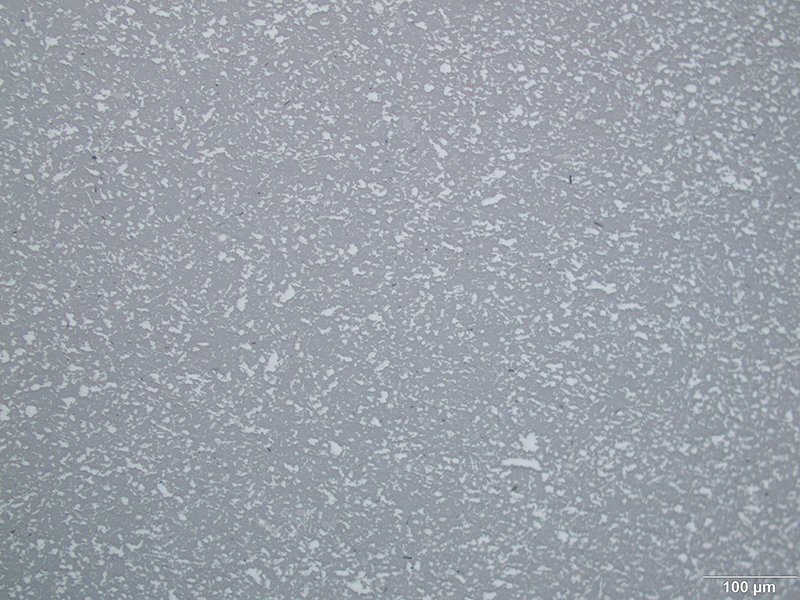

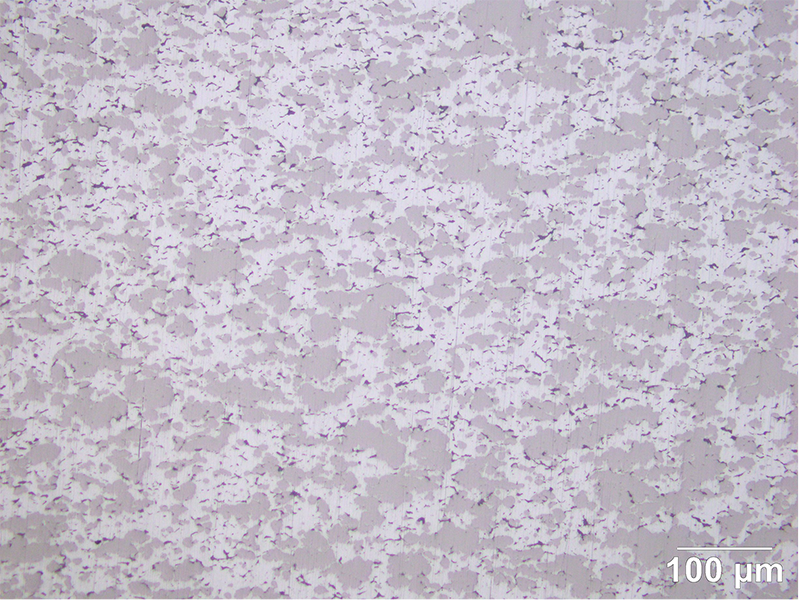

Metallographic Display

AgWC(30) 200×

AgWC(40)

AgWC(50)

Silver Tungsten Carbide Graphite (AgWCC)

Silver tungsten carbide graphite contacts are a commonly used contact material, consisting of two materials, silver (Ag) and tungsten carbide (WC), with added graphite and other additives. Silver has good electrical conductivity and electrical conductivity, tungsten carbide has high hardness and wear resistance, and graphite has good self-lubricating properties. Silver tungsten carbide graphite contacts have excellent electrical and mechanical properties. The high conductivity of silver ensures good current conduction capability of the contacts, and the high hardness and wear resistance of tungsten carbide give the contacts a long service life. In addition, the self-lubricating properties of graphite reduce the friction and wear of the contacts, improving their stability and reliability. Silver tungsten carbide graphite contacts are suitable for high load and frequent switching applications, such as relays, circuit breakers, motors and switches for electrical equipment. They can work in harsh environments such as high temperature and high humidity, and have good corrosion resistance and heat resistance. All in all, silver tungsten carbide graphite contacts are a contact material with good electrical properties, wear resistance and stability. They provide reliable electrical contact and provide long-term stable operation under harsh operating conditions.

|

Product name |

Ag Component(wt%) |

Density |

Conductivity |

Hardeness(HV) |

|

(g/cm3) |

(IACS) |

|||

|

AgWC12C3 |

85±1.0 |

9.6 |

60 |

56 |

|

AgWC22C3 |

75±1.0 |

10 |

58 |

66 |

|

AgWC27C3 |

70±1.0 |

10.05 |

41 |

68 |

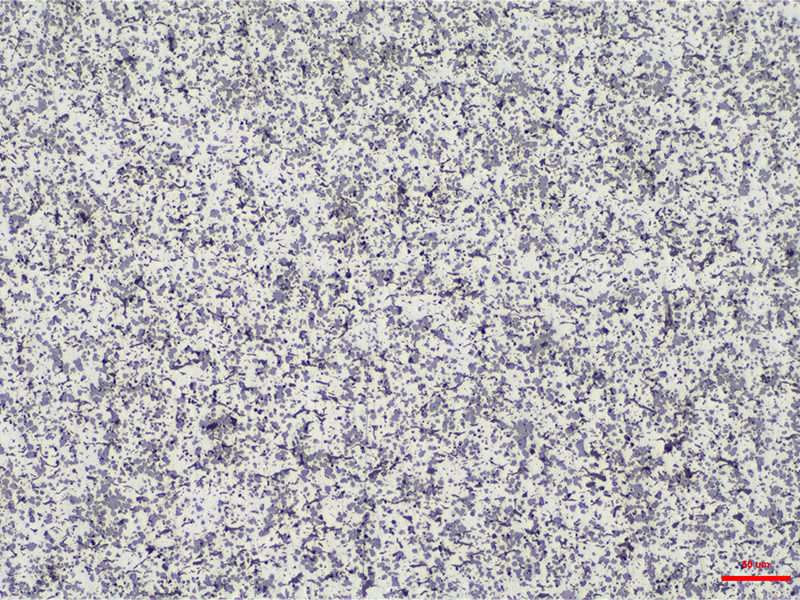

Metallographic Display

AgWC12C3 200X

AgWC22C3

AgWC27C3

Silver nickel Graphite (AgNiC)

Silver nickel graphite contact material is a common contact material, which consists of three components: silver (Ag), nickel (Ni) and graphite (C). It has excellent electrical conductivity, wear resistance and high temperature stability. Silver nickel graphite contact material has the following characteristics: Excellent electrical conductivity: Silver has very good electrical conductivity and can provide low resistance and high current conductivity, while the addition of nickel and graphite can improve electrical conductivity and reduce the current density of contacts. Wear resistance: The addition of nickel and graphite increases the hardness and lubricity of the contacts, which can reduce friction and wear and prolong the service life of the contacts. High temperature stability: Silver nickel graphite contact material has a high melting point and thermal stability, and can maintain stable electrical conductivity and contact reliability in high temperature environments. Oxidation resistance: The addition of nickel and graphite can improve the oxidation resistance of the contacts, delay the oxidation speed of the contacts, and reduce the resistance change of the contacts.

|

Product name |

Ag Component(wt%) |

Density |

Conductivity |

Hardeness(HV) |

|

(g/cm3) |

(IACS) |

|||

|

AgNi15C4 |

95.5±1.5 |

9 |

33 |

65 |

|

AgNi25C2 |

71.5±2 |

9.2 |

53 |

60 |

|

AgNi30C3 |

66.5±1.5 |

8.9 |

50 |

60 |

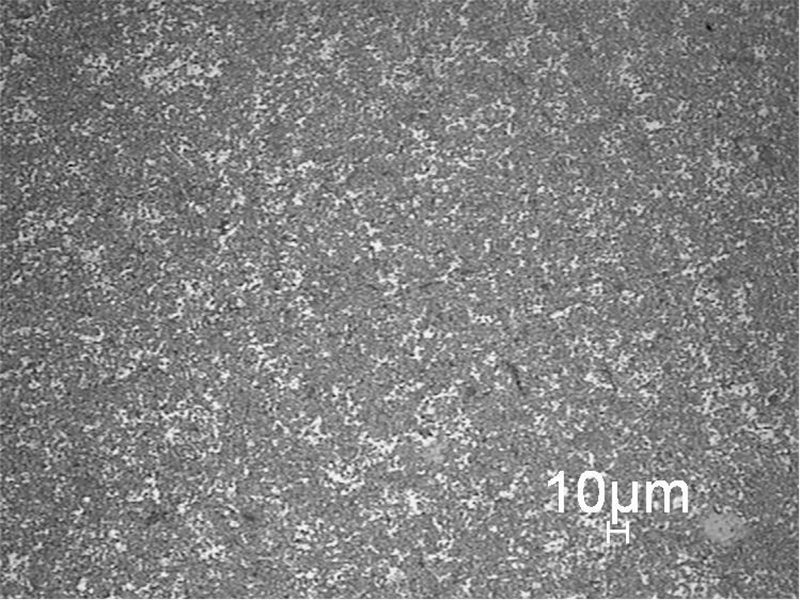

Metallographic Display

AgNi15C4 200X

AgNi25C2

Silver Graphite (AgC)

Silver graphite is a composite material combining silver (Ag) and graphite (carbon). Due to its unique properties, it is widely used in various fields.Silver graphite has become a very common stationary contact material and is typically paired with AgW or AgWC. Most circuit breaker and switch grades contain 95% to 97% silver. Silver graphite has superior anti-welding characteristics and therefore is a good choice when tack welding is an issue. In addition, silver graphite has excellent electrical conductivity due to the typically high silver content and because of the reducing gas formed by graphite. A much softer material than silver tungsten or silver tungsten carbide, silver graphite has a higher erosion rate.

|

Product name |

Ag Component(wt%) |

Density |

Conductivity |

Hardeness(HV) |

|

(g/cm3) |

(IACS) |

|||

|

AgC3 |

97±0.5 |

9.1 |

78 |

42 |

|

AgC4 |

96±0.7 |

8.8 |

75 |

42 |

|

AgC5 |

95±0.8 |

8.6 |

69 |

42 |

Metallographic Display

AgC(4) 200X

Silver tin Oxide (AgSnO2)

Silver tin Oxide has good electrical conductivity and wear resistance. Silver tin oxide contact materials have the following characteristics: Excellent electrical conductivity: Silver has very good electrical conductivity and can provide low resistance and high current conductivity. Wear resistance: The fine tin oxide particles formed when the tin oxide contacts can play a role in lubricating and reducing friction, so that the contact has good wear resistance. Stability: The silver tin oxide contact material is stable and reliable under normal working conditions and can provide long-term stable electrical contact. Corrosion resistance: silver tin oxide contacts have good corrosion resistance and can work in humid and corrosive environments. Silver tin oxide powder material is suitable for 100-1000A AC contactors

|

Product name |

Ag Component(wt%) |

Density |

Conductivity |

Hardeness(HV) |

|

(g/cm3) |

(IACS) |

|||

|

AgSnO2(10) |

90±1 |

9.6 |

70 |

75 |

|

AgSnO2(12) |

88±1 |

9.5 |

65 |

80 |

Metallographic Display

AgSnO2(10)

AgSnO2(12)

Silver Zinc Oxide (AgZnO)

Silver zinc oxide (Ag-ZnO) contact is a commonly used contact material, which is a combination of silver (Ag) and zinc oxide (ZnO). Silver has good electrical conductivity and electrical conductivity, while zinc oxide has high resistivity and high temperature resistance. Silver zinc oxide contacts have good stability and wear resistance under high temperature and high current conditions. The addition of zinc oxide increases the hardness and wear resistance of the contact material, while also providing some degree of arc and burn suppression. Silver zinc oxide contacts have low contact resistance and excellent electrical properties, providing reliable electrical contact during switching operations. They are widely used in switches, relays and circuit breakers of various electrical equipment, and can meet the needs of high load and frequent switching. In addition, the silver zinc oxide contact also has good oxidation resistance, which can prolong the service life of the contact. They are suitable for use under various environmental conditions, including high temperature, high humidity and harsh working environments. All in all, silver zinc oxide contacts are a commonly used contact material with good electrical properties, wear resistance and stability. They play important electrical connection and switching functions in electrical equipment, and can meet various harsh working conditions.

|

Product name |

Ag Component(wt%) |

Density |

Conductivity |

Hardeness(HV) |

|

(g/cm3) |

(IACS) |

|||

|

AgZnO(8) |

92 |

9.4 |

69 |

65 |

|

56 |

||||

|

AgZnO(10) |

90 |

9.3 |

66 |

65 |

|

52 |

||||

|

AgZnO(12) |

88 |

9.25 |

63 |

70 |

|

9.1 |

50 |

|||

|

AgZnO(14) |

86 |

9.15 |

60 |

70 |

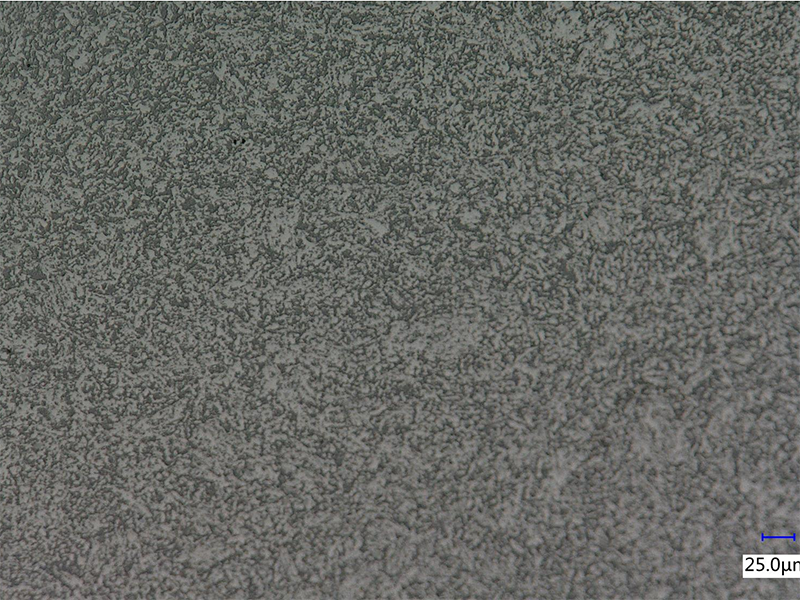

Metallographic Display

AgZnO(12) 200X

AgZnO(14) 200X