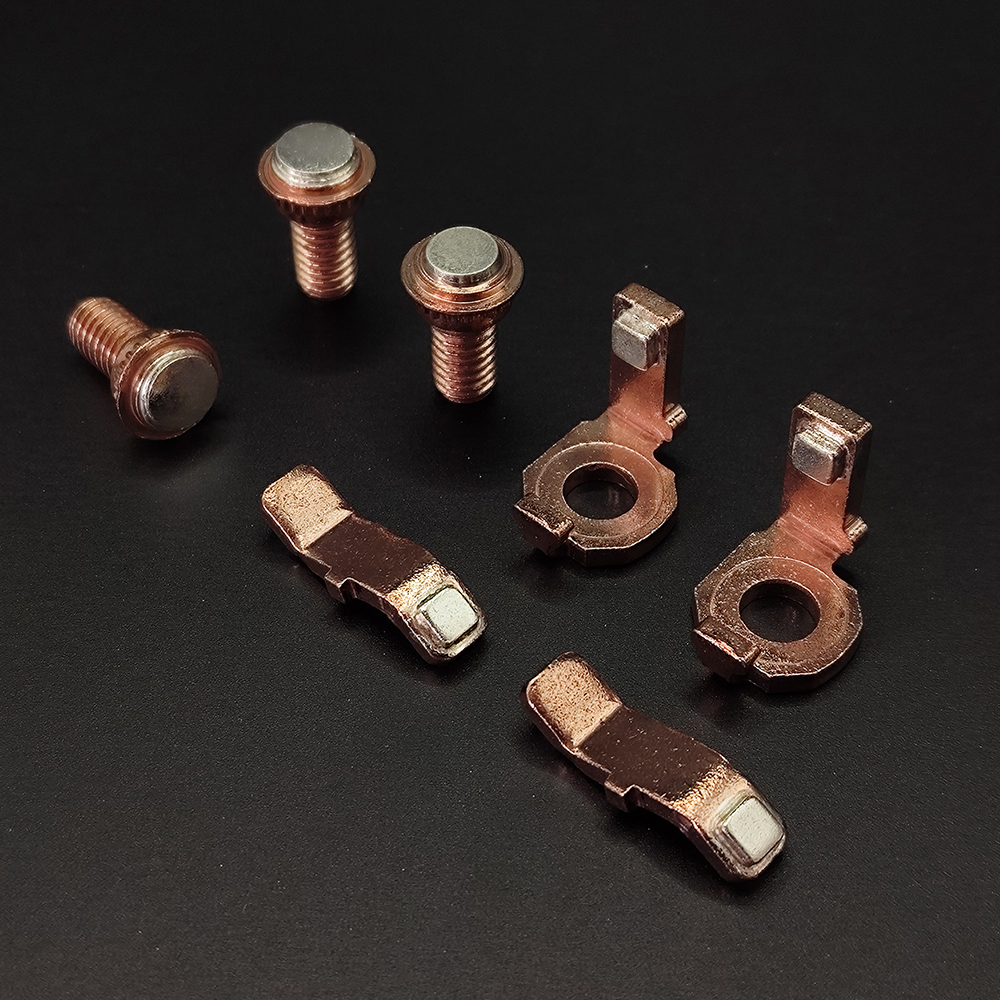

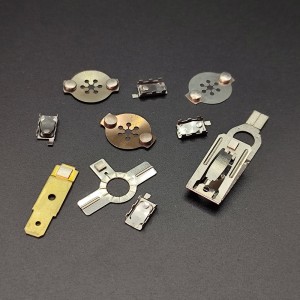

Induction Welding assemblies for Low Voltage Apparatus

Application

Silver contacts induction brazing refers to the process of joining silver contacts using induction brazing techniques. It is a widely used method in the electrical and electronics industry where silver contacts are commonly used for their excellent electrical conductivity and high thermal conductivity.

Indction brazing involves using an induction coil and a medium or high frequency generator to generate heat through electromagnetic induction. The heat is then applied to the silver contact components, causing them to reach the desired brazing temperature. The advantage of induction brazing is that it provides rapid and localized heating, minimizing heat transfer to other areas and reducing the risk of distortion or damage to the surrounding materials.

When brazing silver contacts, it is important to select appropriate brazing materials that are compatible with silver, such as silver-based brazing alloys. The brazing alloy is applied as a filler material to the joint, forming a strong and reliable bond between the silver contact components.

The induction brazing process can be optimized for silver contact assemblies of various sizes and shapes, and it offers benefits such as precise temperature control, high-speed heating, and consistent results. It is a popular method for joining silver contacts due to its efficiency and the ability to produce high-quality, reliable connections.

Silver contacts induction brazing is an efficient, precise and automated welding method with the following characteristics:

● Efficiency: Silver point induction welding uses induction heating, which can quickly heat the welding area in a short time and achieve high-speed welding. Compared with traditional welding methods, production efficiency can be greatly improved.

● Accuracy: Silver point induction welding enables control of welding temperature and time, allowing for accurate control of welding quality during the welding process. Temperature monitoring and control systems during the welding process can ensure the consistency and stability of the welding results.

● Automation: Silver point induction welding usually uses automated equipment to automate the welding process. This not only improves production efficiency, but also reduces the labor intensity of operators.

● Temperature control: Silver point induction welding uses induction heating to quickly heat the welding area to the required temperature, avoiding the problem of overheating or underheating. At the same time, the welding temperature can be accurately adjusted through control equipment.

● Welding quality: Silver-point induction welding uses high-purity silver-point solder. The welded joint has high strength, good weld quality, strong corrosion resistance, and can meet high-demand welding processes. To sum up, silver point induction welding has the characteristics of high efficiency, precision, automation and high quality. It is suitable for welding of various metal materials and is an important method in modern welding technology.